ONE STOP SOLUTION

Multi-color curved surface offset printing machines for plastic cups, plastic bowls, plastic yogurt cups, plastic instant food bowls, plastic food basins, plastic pails, etc.

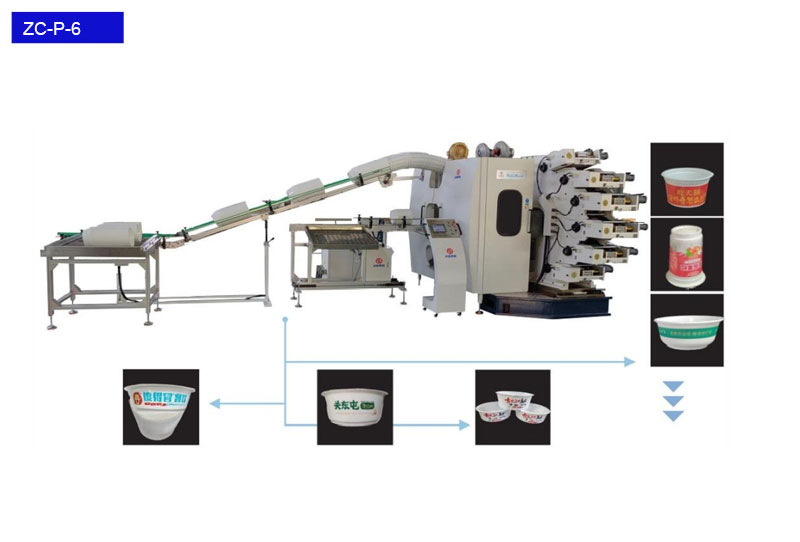

ZC-P-6 Six-color High Speed Plastic Basin Printing Machines

Dear Customer, ZC-P-6 six-color plastic basin printing machine is designed to print all kinds of plastic containers, including large basins, meal prep containers, takeaway bowls, flower pots, milk tea cups, and instant noodle bowls.

This six-color plastic basin printing machine utilizes the pad printing process to apply colorful patterns, text, logos, and various designs onto the surface of plastic products. It achieves high-quality six-color overprinting in a single pass, delivering sharp, vibrant impressions with excellent dot reproduction. The machine is widely used for printing on a variety of plastic containers, including large basins, meal prep containers, takeaway bowls, flower pots, milk tea cups, and instant noodle bowls.

- EXW Price: USD84848

- Lead Time: 30~35 working days after payment received

- Support Language: English, French, Spain, Portugal, Saudi Arabia, etc.

Feature:

This plastic basin printing machine offers optional sloped or lift-feeding, with automated material separation, pre-printing corona treatment, and post-printing UV curing at the mold station. It also features automatic material collection with accurate, reliable counting.

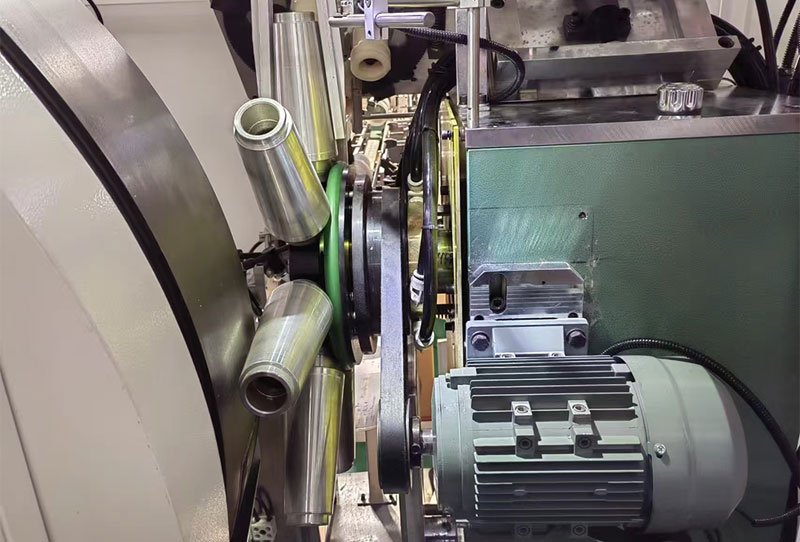

With 3-phase frequency control and stepless speed regulation, the main motor ensures exceptionally smooth and quiet operation.

By employing individual motor drives, each printing unit reduces wear and energy consumption. The 90° swing-away design provides safe and convenient access for cleaning and maintenance.

Fast makeready and precise color registration are achieved thanks to a clip-on plate system (with gluing option) and pre-punched plates.

The machine features double-cup detection and automatic rejection of damaged cups. To protect the printing blanket and mold head from contamination, the printing cylinder instantly retracts when a missing or broken cup is detected.

Application:

ZC-P-6 plastic basin printing machine is widely used for printing on various plastic containers such as large basins, meal prep containers, takeout bowls, flower pots, milk tea cups, and instant noodle bowls. Max. printing speed is 12000pcs/hour, max. basin rim diameter is φ300mm, max. printing height: 160mm, max. basin height: 180mm.

Machine Parameters:

| Model | Main Parameter | |

| ZC-P-6 | Max. Printing Diameter | 1 rubber mode: Φ168mm~Φ285mm 2 rubber mode: Φ90mm~Φ168mm 4 Rubber Sheets Mode:Φ90mm~Φ168mm |

| Max. Printing Height | 160mm | |

| Max. basin (cup/bowl) Height | 30~180mm | |

| Cup(bowl) Body Oblique Angle | <16° | |

| Max. Printing Speed | 21000pcs/hour | |

| Total Power | 28KW/H | |

| Dimensions | 7800*2800*2800mm | |

| Max. Quantity Of Printed colors | 6 Colors | |

| Equipment Weight | 9 Tons | |

Main Machine Features:

Printing Speed: Up to 360ppm, enabling fast responses to large orders ;High-End Printing: Delivers exceptional print quality to meet your high-end needs;Rapid Mold & Plate Replacement: Quick 30-minute changeover for different specifications and short-term orders;Material Compatibility: Supports printing on PP, PET, PC, PS, and eco-friendly plastics.

Color Station Display: Precise and easy pressure adjustment, dual motor drive, ensuring sufficient and even ink supply.

Cup Division/Collection Display: Single-handle adjustment, convenient, quick, and precise.

What Is Work Process Of The Plastic Cup ( Bowl) Printing Machine?

Cup Feeding:

The machine begins by feeding the plastic cups into the printing system. This can be done automatically or manually, depending on the machine’s design.

Pre-Press Treatment

The cups may undergo a corona treatment to increase the surface tension of the plastic, ensuring better adhesion of the ink.

Printing

The machine applies ink to the cup using offset printing, letterpress, or flexographic printing methods, depending on the type of machine;Ink is transferred from a printing plate or screen to the surface of the cup;The printing can include text, logos, and vibrant designs, typically in multiple colors (up to 8 or more).

Drying/Curing

After printing, the ink is cured using UV light (for UV ink) or air drying. The curing process solidifies the ink, making it durable and ensuring it doesn’t smudge.

Cup Collection and Inspection

Once the cups are printed and dried, they are collected and checked for quality.

The machine often has a cup rejection mechanism to remove any defective cups.

Cup Counting and Packaging (Optional)

The machine may automatically count the printed cups and prepare them for packaging, either manually or with an automatic packaging system.

Quick To Change Cup Molds:

Quick To Change Printing Rubber Molds:

FAQs:

1. What is a plastic basin offset printing machine?

A plastic basin offset printing machine is designed for high-quality printing on plastic basins and other similar plastic products. It uses the offset printing process, which transfers ink from a plate to a rubber blanket, then onto the surface of the plastic basin, creating vibrant and detailed prints.

2. What types of designs can be printed on plastic basins?

Plastic basin offset printing machines can print complex logos, text, patterns, and even photographic images. The machine supports full-color printing and can handle multi-color designs to suit various branding and decorative needs.

3. Can the printing withstand regular use and washing?

Yes, the prints are durable and resistant to fading, even with frequent washing or exposure to sunlight. The offset printing process ensures a high-quality finish that adheres well to the plastic, maintaining its integrity over time.

4. What are the main features of your plastic basin offset printing machines?

Our machines are equipped with advanced technology, including automatic color registration, adjustable printing speeds, and precise control for consistent quality. They also feature quick-drying ink systems and efficient ink transfer for superior results.

5. How do I maintain and clean the printing machine?

Regular maintenance involves cleaning the printing plates, blankets, and rollers to ensure smooth operation. It’s recommended to follow the manufacturer’s guidelines for cleaning and maintenance routines. Proper care will extend the machine’s lifespan and ensure consistently high-quality prints.

Contact Our Expert

Categories:

- 8-color Plastic Bowl Cup Printing Machine

- 7-color Plastic Bowl Cup Printing Machine

- 6-color A Plastic Bowl Cup Printing Machine

- 6-color B Plastic Bowl Cup Printing Machine

- 4-color Plastic Bowl Cup Printing Machine

- 6-color Plastic Cup Bowl Basin Printing Machine

- 6-color Plastic Bucket Printing Machine