ONE STOP SOLUTION

Multi-color curved surface offset printing machines for plastic cups, plastic bowls, plastic yogurt cups, plastic instant food bowls, plastic food basins, plastic pails, etc.

ZC-888A 8-color Plastic Bowl Cup Printing Machine

Dear Customer, ZC-888A curved surface offset printing machine is designed to print all kinds of plastic cups and plastic bowls, such as milk tea cups, PET coffee cups, PP milk tea cups, yogurt cups, paper cups, plastic bowls, instant food bowls. Send inquiry to us to get more details.

An 8 colors plastic bowl cup printing machine is an advanced printing device designed for high-quality, multi-color printing on plastic bowl cups. Using offset printing technology, it applies up to eight colors to create sharp, vibrant designs. This machine is perfect for custom branding, promotional products, and event items, ensuring accurate color reproduction and durable prints. It is widely used in industries like food service, retail, and marketing, where personalized or eye-catching designs are essential. The 8 colors plastic bowl cup printing machine offers versatility, efficiency, and precision for creating unique and attractive product designs.

- FOB Price: USD70588

- Lead Time: 30~40 days after payment received

- Support Language: English, French, Spain, Portugal, Saudi Arabia, etc.

Feature:

Printing Capability:

Can print up to eight colors on plastic products.

Suitable for items like milk tea cups, yogurt bowls, foam cups, and other plastic containers.

Automatic Functions:

Automatic cup feeding and pre-press corona treatment.

UV curing at the post-printing station.

Accurate cup counting with optional automatic packaging for labor savings.

Efficient and Stable Operation:

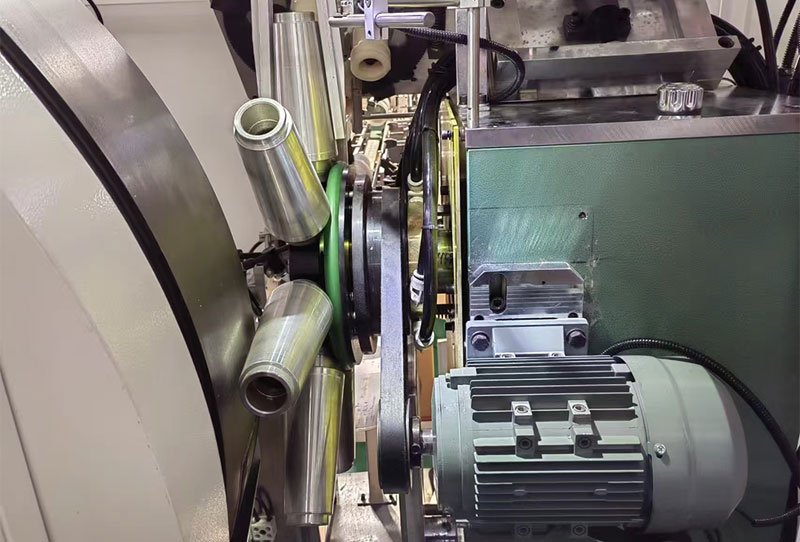

Three-phase frequency control motor with stepless speed regulation.

Dual driving force transmission for precise alignment.

Color Station Control:

Each color station is independently controlled for reduced wear and energy consumption.

Color station rotation (90°) for easy ink cleaning and maintenance.

Ink Consistency:

Constant temperature system to maintain ink fluidity and viscosity, ensuring better print quality.

Hanging-type printing plate installation for quick alignment.

Special punching machine for accurate and reliable color registration.

Safety Features:

Double cup detection and automatic rejection of broken cups.

Instant detachment of the printing roller to protect from damage when defective cups pass through.

Application:

ZC-888A 8 color plastic bolw cup printing machine is designed for printing all kind of thermoforming cups and bowls, injection cup and bolws. Max. printing speed is 24000pcs/hour, max. cup (bowl) rim diameter is φ180mm, max. printing height: 160mm, max. cup (bolw) height: 235mm.

Machine Parameters:

| Model | Main Parameter | |

| ZC-888A | Max. Printing Diameter | Three rubber mode: Φ168m 6 Rubber Sheets Mode: Φ95mmm |

| Max. Cup(bowl) Rim Diameter | Φ180mm | |

| Max. Printing Height | 160mm | |

| Max. Cup(bowl) Height | 235mm | |

| Cup(bowl) Body Oblique Angle | <16° | |

| Max. Printing Speed | 24000pcs/hour | |

| Total Power | 30KW/H | |

| Dimensions | 6600*2800*2800mm | |

| Max. Quantity Of Printed colors | 8 Colors | |

| Equipment Weight | 8.8 Tons | |

Main Machine Features:

Printing Speed: Up to 360ppm, enabling fast responses to large orders ;High-End Printing: Delivers exceptional print quality to meet your high-end needs;Rapid Mold & Plate Replacement: Quick 30-minute changeover for different specifications and short-term orders;Material Compatibility: Supports printing on PP, PET, PC, PS, and eco-friendly plastics.

Color Station Display: Precise and easy pressure adjustment, dual motor drive, ensuring sufficient and even ink supply.

Cup Division/Collection Display: Single-handle adjustment, convenient, quick, and precise.

What Is Work Process Of The Plastic Cup ( Bowl) Printing Machine?

Cup Feeding:

The machine begins by feeding the plastic cups into the printing system. This can be done automatically or manually, depending on the machine’s design.

Pre-Press Treatment

The cups may undergo a corona treatment to increase the surface tension of the plastic, ensuring better adhesion of the ink.

Printing

The machine applies ink to the cup using offset printing, letterpress, or flexographic printing methods, depending on the type of machine;Ink is transferred from a printing plate or screen to the surface of the cup;The printing can include text, logos, and vibrant designs, typically in multiple colors (up to 8 or more).

Drying/Curing

After printing, the ink is cured using UV light (for UV ink) or air drying. The curing process solidifies the ink, making it durable and ensuring it doesn’t smudge.

Cup Collection and Inspection

Once the cups are printed and dried, they are collected and checked for quality.

The machine often has a cup rejection mechanism to remove any defective cups.

Cup Counting and Packaging (Optional)

The machine may automatically count the printed cups and prepare them for packaging, either manually or with an automatic packaging system.

Quick To Change Cup Molds:

Quick To Change Printing Rubber Molds:

FAQs:

1. What is a curved offset plastic cup printing machine, and how does it work?

A curved offset plastic cup printing machine is specially designed to print on the curved surfaces of plastic cups, offering high-quality, precise, and durable prints. It uses offset printing technology, where an inked image is transferred from a plate to a rubber blanket and then onto the cup, ensuring smooth and vibrant results on curved surfaces.

2. What types of plastic cups can your curved offset printing machine print on?

Our curved offset printing machines can print on various plastic cups, including PET, PP, and PS cups, regardless of their shape or size. Whether it’s a simple single-wall cup or a more complex double-wall cup, our machine guarantees superior print quality.

3. What are the advantages of using curved offset printing over other methods?

Curved offset printing provides several advantages, including high-quality prints, faster production speeds, and greater flexibility in design. It offers crisp details, vibrant colors, and excellent adhesion to plastic materials, making it ideal for mass production and custom designs.

4. How fast is the production speed of the curved offset plastic cup printing machine?

Our curved offset printing machine can handle high-speed production, with speeds up to 400 cups per minute, depending on the model and configuration. This makes it highly efficient for large-scale printing operations, ensuring rapid turnover without sacrificing print quality.

5. Can the machine print multi-color designs on curved cups?

Yes, our curved offset plastic cup printing machines are capable of printing multi-color designs. With advanced color control technology, the machine ensures accurate color reproduction and alignment across multiple colors, resulting in vibrant and detailed designs.

6. How easy is it to maintain the curved offset printing machine?

Our machines are designed for easy maintenance and minimal downtime. They come with automated cleaning functions, and our support team offers regular maintenance guides. Additionally, we provide spare parts and expert assistance to ensure the machine runs smoothly for years.

Contact Our Expert

Categories:

- 8-color Plastic Bowl Cup Printing Machine

- 7-color Plastic Bowl Cup Printing Machine

- 6-color A Plastic Bowl Cup Printing Machine

- 6-color B Plastic Bowl Cup Printing Machine

- 4-color Plastic Bowl Cup Printing Machine

- 6-color Plastic Cup Bowl Basin Printing Machine

- 6-color Plastic Bucket Printing Machine